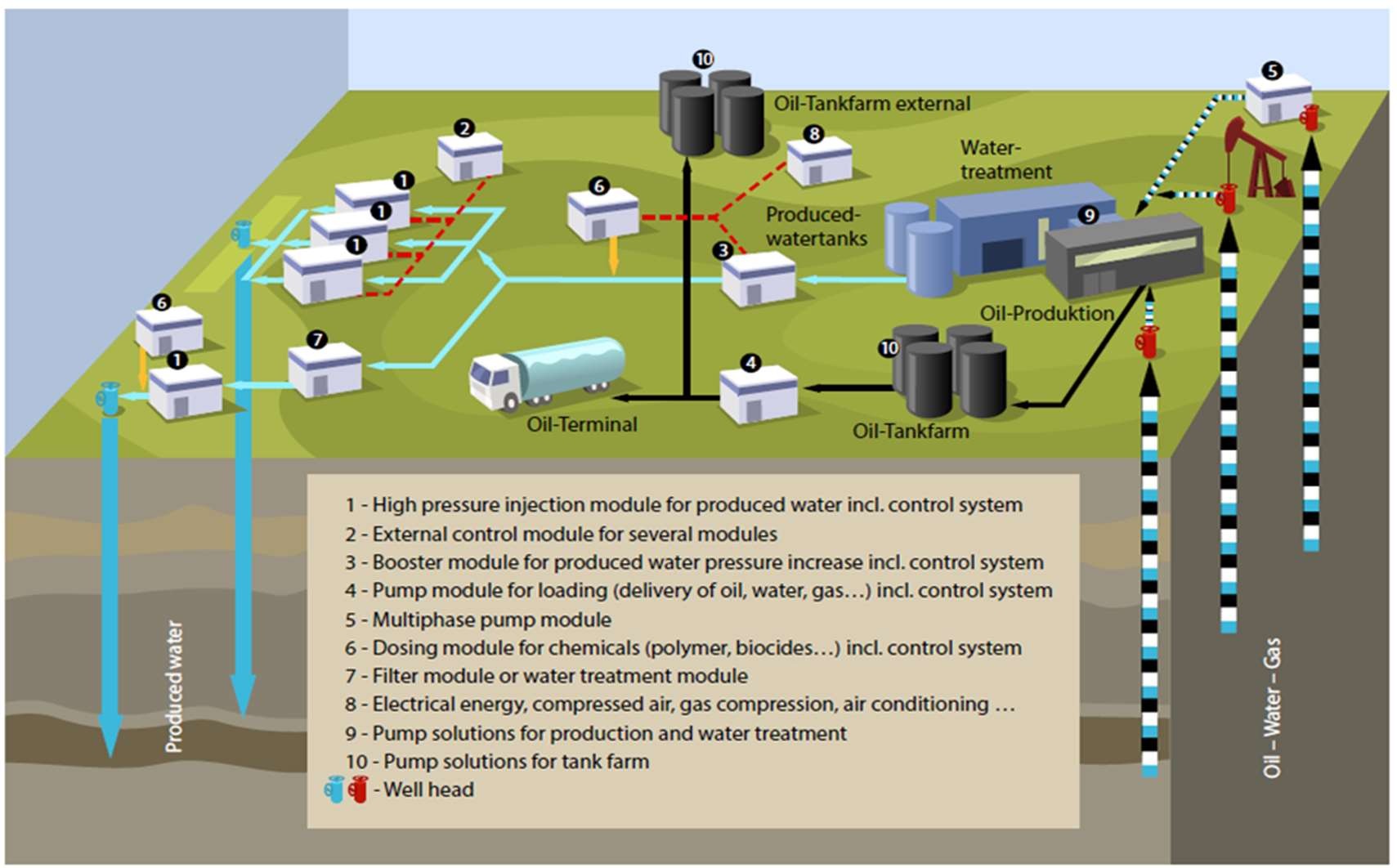

Produced Water Treatment & Injection

Zulal supplies complete produced water treatment solutions with our partner SONNEK Engineering, both of which consists of a team of experienced design engineers, field engineers & technicians highly skilled for mounting and servicing of all kind of rotating equipment. Our plants are built depending on the size and final destination either in Sonnek workshop in Vienna (Austria) or at the production site.

We provide the entire engineering and system design, manufacture the modules, run the factory acceptance testing as well as the on-site commissioning, training and start-up and carry out all scheduled service and maintenance work.

Some Key Industrial Applications include:

- Modular containerized systems or skid-based systems for produced water injection (formation water)

- Booster pump systems for liquids such as produced water and salt water in general

- Industrial water treatment solutions

- Modular solutions for produced water treatment

- Fully automized systems for dewatering systems at tunnel constructions

- Systems for multiphase pumping

- Loading and unloading systems for chemical and oil tank farms

Our turnkey systems treat, boost and eventually pump the reservoir water under high pressure into the reservoir through flood wells. The plug-andpump systems are prefabricated and tested as container or skid constructions – after just a simple installation on-site – ready for operation. They are equipped with intelligent control with remote access, thus allowing for an unmanned, 24/7 continuous operation.

Benefits of our Injection Systems:

- Modular containerized solutions for on-shore oil and gas fields

- Skid-based solutions for offshore und stationary installation

- SONNEK turnkey Plug & Pump solution

- Flexible systems for changing locations

- Weather-proof for all climates

- Corrosion resistant against produced water with high chloride contents

- Delivery rates from 1 m³/h to 150 m³/h per injection module

- Delivery rate can be adjusted at a ratio of 1:10 without efficiency loss when reducing the flow rate.

- Skid pressure rates up to 700 bar

- Leak-free and emission-free execution

- Control system for fully automated operation and variable delivery and pressure rates

- API674 high-pressure pumps